Submission information

Submission Number: 125

Submission ID: 218

Submission UUID: 7b80e5f5-0deb-4db1-a0e8-21054dfc3030

Submission URI: /form/project

Created: Fri, 11/05/2021 - 16:14

Completed: Fri, 11/05/2021 - 16:14

Changed: Thu, 05/05/2022 - 04:01

Remote IP address: 76.118.242.253

Submitted by: Jingru Benner

Language: English

Is draft: No

Webform: Project

| Received Sent | 0 |

|---|---|

| Accept and Publish Sent | 0 |

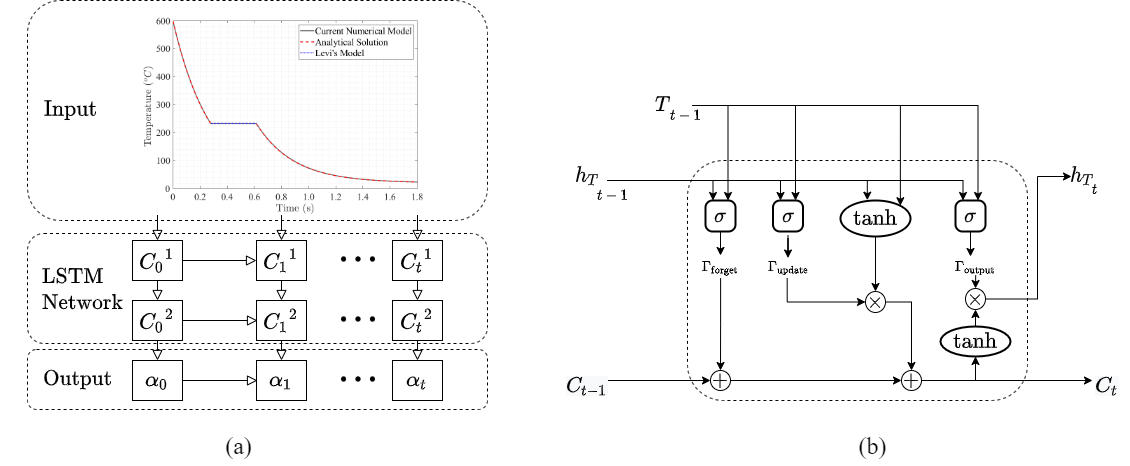

| Project Title | Using Long Short Term Memory to Obtain Particle Attributes during the Encapsulation Process of High Temperature Phase Change Materials |

| Program | Northeast |

| Project Image |

|

| Tags | deep-learning (303), machine-learning (272), matlab (2), openfoam (327) |

| Status | Complete |

| Project Leader | Jingru Benner |

| jingru.benner@wne.edu | |

| Mentor(s) | |

| Student-facilitator(s) | Rebecca Shannon |

| Mentee(s) | |

| Project Description | The main objective of this project is to apply Long Short Term Memory (LSTM), a recurrent neural network (RNN) algorithm to analyze an inverse heat conduction problem with phase change. The inverse heat conduction problem is associated with the manufacturing process of micro-encapsulated phase change particles (MEPCM) for high temperature applications. These particles are composed of a metallic or alloy core, and a glassed based shell. The final dimension of the particles in particular the core to shell ratio is of great importance to the performance of the particles when used for thermal energy storage applications. We are interested in obtaining the size of the particles during a process called Flow Mold Casting (FMC). During the FMC process, the concentric cylindrical microwire with a metal core and glass shell is melted by high power pulsating laser to form encapsulated particles. As opposed to a standard heat conduction problem with well-defined boundary conditions and initial condition, from which we can solve for the temperature distribution, the surface condition of the particle, the dimension of the particles, and the melting state of the particles during this process is challenging to obtain, therefore, making the mathematical problem ill-posed. To compensate the lack of information, the temperature change of the particle over certain time interval may be measured using a high speed thermal camera, which is called the cooling curve. We attempted to obtain the dimension of the MEPCMs based on the cooling curve with the help of LSTM model. In a previous study supported by MGHPCC and NorthEast Cyberteam, a numerical model that represents this manufacturing process was developed and verified in OpenFOAM. The numerical model can calculate the cooling curve of MEPCM particles for a wide range of material properties, diameter, core to shell ratios and surface conditions. The output of the numerical model will be used to generate training data for the machine learning model. Since the process is time dependent and cooling curve reflects the temperature change with time, we use LSMT, a recurrent neural network model, to identify the diameter of the core and the core to shell ratio. The testing data will be provided by the numerical model in OpenFOAM. |

| Project Deliverables | The main project deliverables include: 1) Obtain training and testing data in OpenFOAM 2) Build the LSTM model frame in MATLAB 3) Validate the LSTM model for a wide range of thermophyical properties and boundary conditions |

| Project Deliverables | |

| Student Research Computing Facilitator Profile | |

| Mentee Research Computing Profile | |

| Student Facilitator Programming Skill Level | Some hands-on experience |

| Mentee Programming Skill Level | |

| Project Institution | Western New England University |

| Project Address | 1215 Wilbraham Rd Springfield, Massachusetts. 01119 |

| Anchor Institution | NE-MGHPCC |

| Preferred Start Date | |

| Start as soon as possible. | Yes |

| Project Urgency | Already behind3Start date is flexible |

| Expected Project Duration (in months) | 6 months |

| Launch Presentation | |

| Launch Presentation Date | |

| Wrap Presentation | |

| Wrap Presentation Date | |

| Project Milestones |

|

| Github Contributions | |

| Planned Portal Contributions (if any) | |

| Planned Publications (if any) | one conference paper in the related field |

| What will the student learn? | What will the student learn: 1)Post processing data from OpenFoam, 2)Basics of Machine Learning, in particular RNN models |

| What will the mentee learn? | |

| What will the Cyberteam program learn from this project? | |

| HPC resources needed to complete this project? | |

| Notes | |

| What is the impact on the development of the principal discipline(s) of the project? | |

| What is the impact on other disciplines? | |

| Is there an impact physical resources that form infrastructure? | |

| Is there an impact on the development of human resources for research computing? | |

| Is there an impact on institutional resources that form infrastructure? | |

| Is there an impact on information resources that form infrastructure? | |

| Is there an impact on technology transfer? | |

| Is there an impact on society beyond science and technology? | |

| Lessons Learned | |

| Overall results |